dynamix®

Quick dispersion pigments

you can just stir in

Create any batch size without grinding, every pigment

is 100% pure color.

Skip the mill with Dynamix® and just stir it in. Every pigment is 100% color, no additives or filler.

You’ll get full pigment dispersions in minutes leading to faster product development and streamlined production.

As a color pigment manufacturer, we know cutting out color development variability creates efficient processes.

No need for solvents, resins, dispersion and stability additives,

Dynamix gives you 100% pure color

Skipping the mill and extra testing equipment, reducing capital expenses

Small or large batch sizes allows for just-in-time mixing, saving time and overall production costs

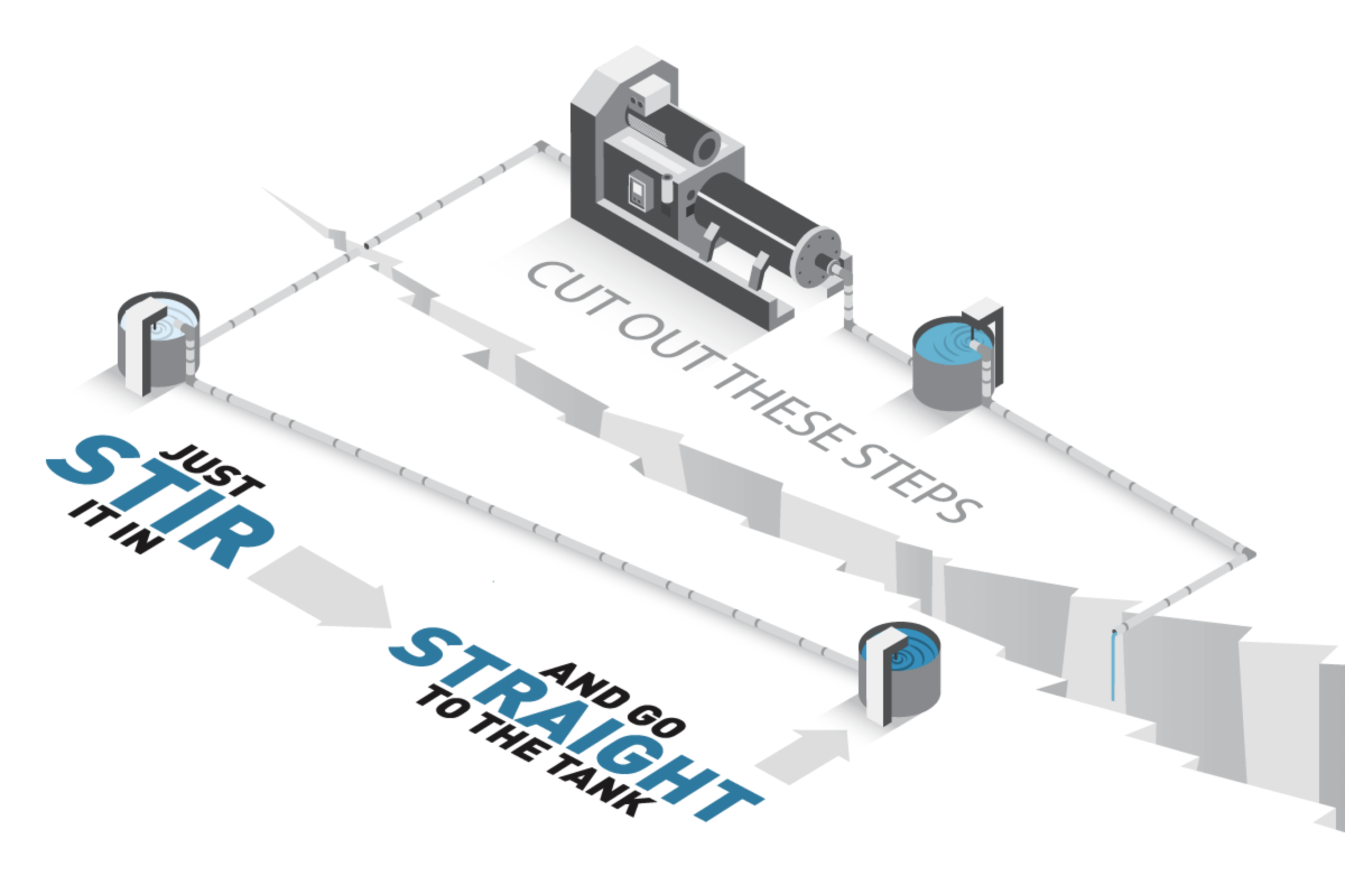

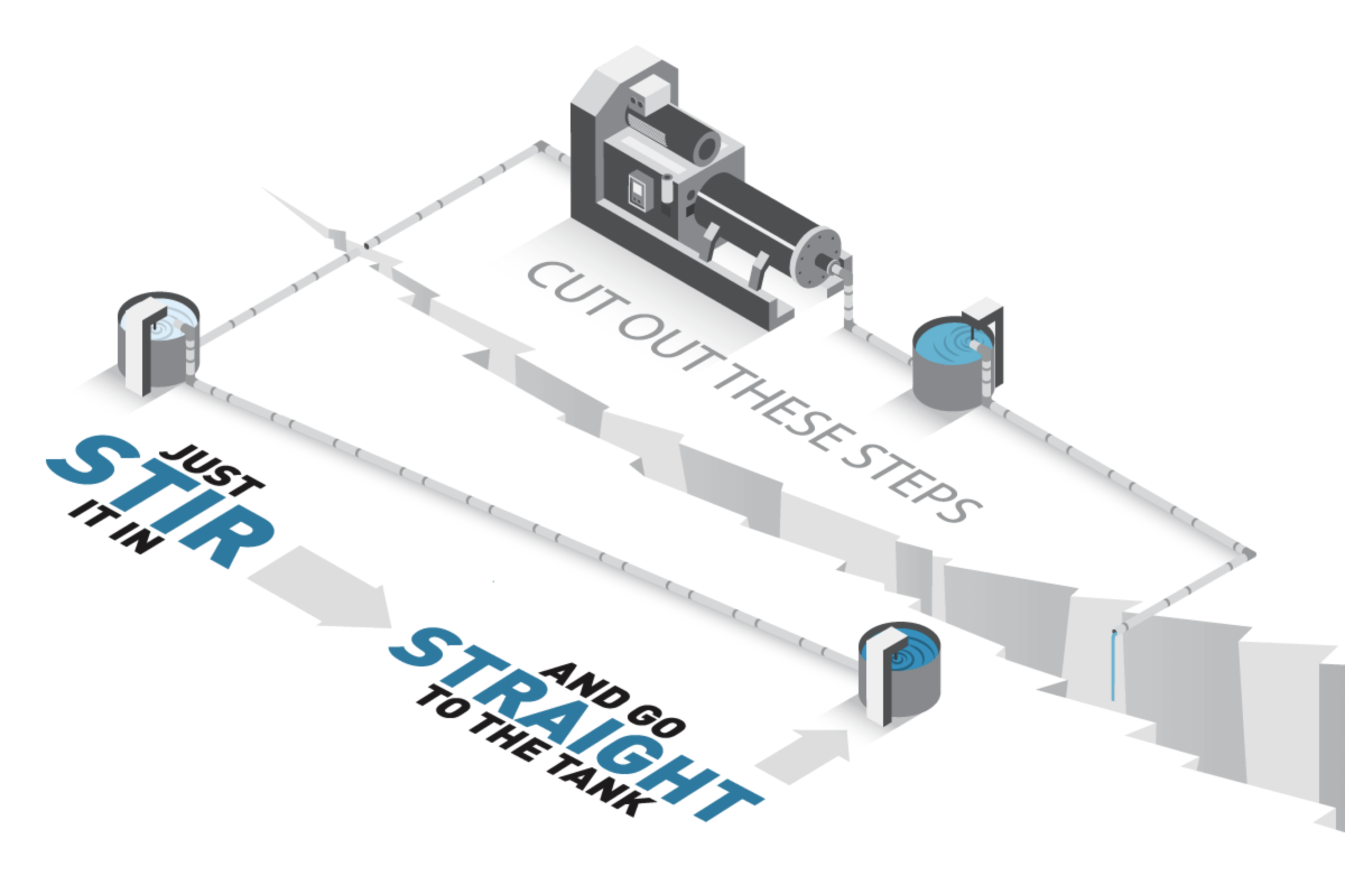

SKIP STEPS

Achieve 100% Pure Color Dispersions With Dynamix

CREATE PROFIT

Pre-Mix Tank

Small Media Mill-Time consuming & costly equipment to make dispersions

Pass Tank – quality of dispersions tested here

Let-down Tank-Dispersed pigment converted into paint or coating

Pre-Mix Tank

Small Media Mill-Time consuming & costly equipment to make dispersions

Pass Tank – quality of dispersions tested here

Let-down Tank-Dispersed pigment converted into paint or coating

What Is Pure?

Things aren’t always what they seem.

Standard liquid color dispersions aren’t just colored pigment. Use of solvents, resins, dispersion and stability additives mean you’re often only getting about 60% pigment. The rest is just filler.

Applications for Liquid Color Dispersions

Since pigments are a key component in the formulation and tinting of coatings and plastics, you know they also play a pivotal role in performance. By being able to mix in color pigments without the need for grinding, you can ensure you’re getting: maximum color efficiency, lower quantities of costly pigments, predictable results that can be duplicated, and stabilization.

At Shepherd Color, we understand and take very seriously the idea that pigment dispersions are not a one-size-fits-all solution. We treat every client, industry, and application individually and ensure all of our mix-in color dispersions provide the perfect balance of stability, compatibility, ease of use, tinting strength and control, color consistency, color retention, chemical resistance, durability, and overall aesthetics.

These benefits make liquid color dispersions applicable to various industries and applications. Most commonly, manufacturers use pigment dispersions to color many types of materials, including paints and coatings or plastics. As a color pigment manufacturer, we’ve seen our innovative solutions used in decorative, industrial, textile, plastic, and even ink applications.

Not sure if pigment dispersions are suitable for your application? We can help. Contact us to request a free sample.

Coil Coatings

Liquid Spray

Powder Coatings

Inks

Masonry Coatings

UV Cured Coatings

High Heat Coatings

Can’t find what you’re looking for?

Ask us!